How can I get my aerospace engineering interest off the ground?

Recently, a mechanical engineering student asked this question in response to an advertisement at http://aerofluids.com/ARPL/. He wants to make a career shift right out of undergraduate engineering school. This student needs to become proficient in aircraft design in 2 years. He must formulate a plan and stick to it religiously.

Time and Money: Your time is far more valuable than you think. Since the timeline is 2 years, you must obtain the fundamentals fast; your training will be steep and expensive. Your competitors may have spent the last 10 years studying, building, flying and discussing aircraft. Their experiences will initially help them find better solutions faster. Your primary advantage is dedication and more efficient learning. If you can trade money for time, take it.

Reference Books: You must understand and recall considerable technical information. The fundamentals are contained in textbooks and reference books. You don’t need to buy the newest editions. Solve the problems. Start with these:

- Funamentals of Aerodynamics, Anderson

- Hoerners Lift and Drag

- Theory of Wing Sections, Abott and von Doenhoff

- Aircraft Design, Raymer

- Any flight dynamics book by Roskam

- Boundary Layer Theory, Schlichting (older/used editions are ok)

For a quick high-level overview of an entire aircraft, study the Modern Fighting Aircraft line of books (example: MFA: Falcon and MFA: A-10)

Technical Journals: The aerospace journals contain practical and theoretical design cases. Set aside a couple of hours per week to systematically read journals. Look up the unfamiliar concepts in an aerodynamics book (e.g. Anderson). Start with these journals:

- AIAA Journal of Aircraft (ISSN 1533-3868, FREE e-copy at UA library)

- Annual Review of Fluid Mechanics

- AIAA Journal

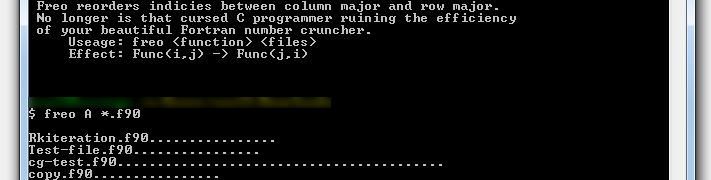

Computer Programming: While not strictly aerospace engineering, proficiency at programming is necessary for analysis and visualization. You should be comfortable with Fortran and C for high performance computing. A scripting and plotting language such as Matlab, Python, Clojure, etc. is useful. If starting from scratch, try something like Think Python, HTDP or even SICP. For technical computing, try Numerical Recipes or NM (Hamming).

Projects: Work on projects continuously. Write-up your projects and publish the results on your professional blog.

Naturally, accepting a position in a design lab would accelerate this process.